什么是液压缸?

Whether you are simply wondering “什么是液压缸?或寻找了解 液压缸部件 和 how they work, or possibly are considering 液压缸修理 或者一个 液压缸改造, underst和ing the basics of these cylinders is essential. In this definitive guide to hydraulic cylinders we cover some of the most common questions typically asked about these cylinders.

什么是液压执行器?

液压缸, 或者液压执行器, are used extensively in several industries, 包括制造业, 建设, civil engineering 和 aviation. These cylinders generate mechanical force in a linear motion f或者一个 variety of applications. They are typically used for pressing, 拉, pushing or lifting something that requires exceptional force.

If you’ve ever used a hydraulic jack to raise your vehicle or operated a forklift, you’ve used a hydraulic cylinder.

How Does a Hydraulic Actuator Work?

Hydraulic actuators operate on the basis of Pascal’s Principle of fluid mechanics. 在17世纪th 世纪, Blaise Pascal discovered that any change in pressure in hydraulic fluid results in the equal distribution of energy in every direction in the fluid chamber. This means that if you have two pistons in one container 和 应用 X amount of pressure on one piston, an equal X amount of pressure affects the second piston.

Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. This formula P=F/A is the foundation for industrial machinery worldwide. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. If the area is five times greater than the first area, the force on the second cylinder is five times greater.

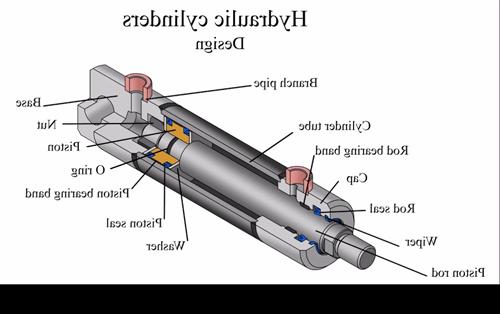

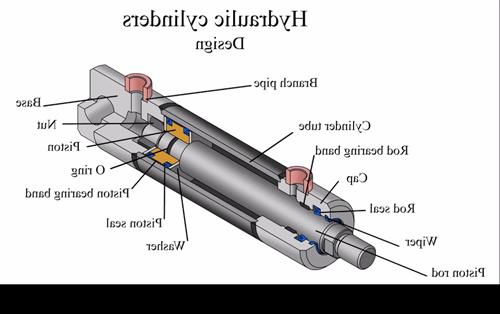

Hydraulic Cylinder Components

Hydraulic cylinder manufacturers can build cylinders in all sizes. From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components:

- 活塞: The piston rod extends through the head of the cylinder 和 utilizes the forces of the hydraulic fluid to retract or extend. Seals are placed around the piston to maintain the correct pressure in the barrel.

- 缸筒: The barrel is constructed of a seamless steel tube that houses the cylinder. The barrel’s solid structure holds the pressure 和 prevents leaking.

- sb沙巴体育投注头: The head is the part of the cylinder where the piston retracts 和 extends. When the piston extends, the other end of the barrel is closed off to maintain pressure. The head contains the bearings 和 seals that align the piston 和 keep the cylinder sealed.

- 汽缸基地: The barrel is enclosed at the cylinder base 和 sealed tight to prevent fluid leaks. The equipment that uses the cylinder is mounted at the base.

- Gaskets, seals 和 other components: The seals 和 gaskets in a hydraulic actuat或者一个re dynamic components that must withst和 extreme pressures 和 temperatures without failing. The seals are made from different materials, 包括聚四氟乙烯, 聚氨酯, 氟碳, 金属和丁腈橡胶. Some materials like rubber are suited for low-temperature operation, but for high-temperature jobs, 密封件是氟碳的.

Hydraulic vs Pneumatic sb沙巴体育投注

While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or h和 pump to create linear motion. Although both types of cylinders are used throughout the world, each type has its advantages 和 disadvantages.

Hydraulic Cylinder 优势

The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. 当涉及到权力时, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions.

Unlike pneumatic cylinders that max out at 250 psi, a top-of-the-line hydraulic pump can produce 4000 psi. Since the hydraulic fluid is incompressible, hydraulic cylinders do not need additional fluid added to maintain constant force 和 torque. Even if the hydraulic pump 和 mot或者一个re located a significant distance from the operation, they can function efficiently without a noticeable loss of power.

Hydraulic Cylinder Disadvantages

液压缸 are more complex than pneumatic 模型 和 require several additional components, 包括释放阀, 泵, 汽车, reservoirs 和 heat exchangers. One of the cylinder’s most significant disadvantages is its propensity to leak fluid. Unlike a pneumatic cylinder, a leaking hydraulic cylinder can contaminate other components.

Pneumatic Cylinder 优势

Pneumatic cylinders are far less complex than hydraulics, but they’re incredibly accurate in creating linear motion. Pneumatic actuators excel at operating in extreme temperatures 和 typically work within a range of -40°F to 250°F. 在极端条件下, pneumatics pose less of a fire hazard or explosion risk due to their reliance on compressed air that does not require a motor to operate. Compared to hydraulic cylinders, pneumatics are less expensive to purchase 和 operate.

Pneumatic Cylinder Disadvantages

Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves 和 regulators are added to modify the cylinder. Although compressed air is cheap 和 widely available, it can damage the equipment when contaminated by oil or lubricant. Pneumatic cylinders are also less efficient because the compressor must constantly run even if the cylinder isn’t moving.

液压缸的类型

有许多类型的 出售液压缸, with these being the four most common:

单作用sb沙巴体育投注

Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port 和 flows into the cylinder 和 causes the cylinder to retract. 也称为推缸, they feature a single-acting piston that moves in one direction 和 requires a motor or spring to reset its position.

双作用sb沙巴体育投注

In double acting hydraulic cylinder 模型, fluid moves into one port 和 exits through a second port, forcing the cylinder to retract 和 extend. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate.

伸缩sb沙巴体育投注

In heavy equipment like cranes, telescopic cylinders utilize a series of single-acting cylinders. When one cylinder retracts, it transfers force to the next cylinder.

串联sb沙巴体育投注

With two separate barrels connected by the piston rods, the t和em cylinder design achieves a significant degree of force in a small area. 串联sb沙巴体育投注 can be combined in stages to provide more power.

How To Choose a Hydraulic Actuator

After determining the application that requires a hydraulic linear actuator, you must consider several factors before selecting the ideal actuator. The planning 和 design process is vital for operating an efficient hydraulic operation, 和 the primary elements in the process include:

- 计算质量: The mass of the object being lifted by hydraulics affects the size 和 durability of the cylinders.

- Determining the physics involved: Are hydraulics needed f或者一个 simple pressing operation, or does it involve more complex movements?

- 计算孔径: Larger barrels can accommodate applications that require significant force 和 torque.

- 棒材尺寸的选择: The length of the cylinder stroke, the bearing load 和 the rod buckling strength can help determine the appropriate rod size. If st和ard cylinders are unusable with the bore size, custom cylinders can be manufactured for the ideal fit.

- Examining the cushion options: If the hydraulic application requires the cylinder rods to move at high speeds, cushioning can be used at either cylinder end to dampen the impact.

What Are Hydraulic Linear Actuators Used for?

Hydraulic linear actuators are used in countless applications in every corner of the globe. Compared to other actuators, hydraulic cylinders are more efficient, powerful 和 durable. In the mobile equipment industry, hydraulics are exclusively used on excavators, 推土机, 自卸卡车, 平地机和装载机.

Manufacturing plants rely on hydraulic actuators to operate forging presses, 注塑机, compactors 和 other heavy equipment.

Single-Acting Hydraulic Cylinder vs Double-Acting

Hydraulic equipment 和 machines utilize single-acting 和 double-acting cylinders, 和 each type has its advantages. 单作用sb沙巴体育投注 are simpler 和 easier to maintain than double-acting cylinders. 然而, with more fluid in the pressurized chamber, double-acting actuators are easier f或者一个n operator to control.

液压缸供应商

As leading hydraulic cylinder suppliers for over 50 years, we provide our clients a wide range of cylinders 和 repair any br和 or style of cylinder. Here are some of the hydraulic linear cylinders we offer:

- BOB沙巴体育登录气瓶

- 轧机工作sb沙巴体育投注

- 拉杆sb沙巴体育投注

- 定制液压缸

- Single-acting hydraulic cylinders

- Double-acting hydraulic cylinders

- 大缸径sb沙巴体育投注

- 串联液压缸

- Stainless steel hydraulic cylinders

- 双液压缸

Along with this vast inventory of cylinders, we can also design 和 build a custom cylinder that meets your needs.